Jar Mills are available in bench or floor models and have one to six jar capacities in 1 2 or 3 tiers They are used for wet or dry grinding mixing and blending of ores chemicals ceramics glass and more Benchtop Labmill is lightweight and compact and easily adjusts to four sizes of milling jars 16 320oz 10L Jars made of High Density Polyethylene fit in metal reinforcing

High grade quality grinding mills are now in Canada Explore our huge range of ball mills SAG mills roller mills vertical mills and miscellaneous grinding mills 1 604 534 5313 2′ X 4′ MARCY ROD BALL MILL WITH CLASSIFIER; ID L02558 30″ X 54″ DENVER STEEL LINED BALL MILL 10 HP; Sold ID L01740 [LBS ] ″ 3″ ALUMINA

Ball s Grist Mill By 1809 John and George Ball had constructed a four storey grist mill here on Twenty Mile Creek Equipped with two run of stones the mill provided flour for British troops during the War of 1812 It was expanded during the 1840s and by the end of the decade was part of a complex which included sawmills and woollen factories

1 ·ميتروبوليتانو ينافس لاستضافة نهائي دوري الأبطال 2027 فاسكيز فينيسيوس أثبت أنه الأفضل في العالم كورتوا يوجه رسالة إيذاء لبرشلونة

·The ball mill hydrocyclone circuit and the ball mill screen circuit were sampled in order to measure and compare the performance of the circuits The ball mills are different in design Therefore simulation studies were carried out to eliminate the differences in factors affecting the performance of the circuits such as milling conditions

Ball mills can be used to further break down or refine a single material or you can place multiple materials into a ball mill jar to mix as you pulverize this is a very common industrial solution for mixing glazes that require the smallest of mesh sizes Ball mills basically function like a mortar and pestle but on a much larger scale

Description There are a lot of different types of grinding mills and each use different types of balls iron/steel and forged/stamped parts to do the job Each type of grinding mill is different and has different parts that are used to do the job Canada $ Mexico $ Ghana $ and Democratic Republic of the Congo $22

Ball Mills Ball mills have been the primary piece of machinery in traditional hard rock grinding circuits for 100 years They are proven workhorses with discharge mesh sizes from 40M to <200M Use of a ball mill is the best choice when long

Offering two times the life of a standard carbide end mill the end mills in these sets have two milling ends so you can switch to the opposite end when one end wears out Made of solid carbide they re harder stronger and more wear resistant than high speed steel for the longest life and best finish on hard material

·Vancouver B C Canada SAG 2 0 0 6 II 316 reserves are to a large extend in the UG2 reef The UG2 platinum ore is RoM ball mills are commonly used for primary grinding in circuits where

·The document summarizes the ball mill which is a grinder used to grind and blend materials It discusses the basic parts of a ball mill including the hollow cylinder and balls It then explains the principle of operation through impact and attrition The document also covers the theory behind maintaining critical speed for optimum efficiency

·The ball mill understudy has as previously referred to a cylindrical length of m a length between supports of m and an inner diameter of m It is divided into two chambers the first is m long with a maximum ball diameter of 80 mm and a density of 30%; the second chamber is m long with a maximum ball diameter of

·The ball mill hydrocyclone circuit and the ball mill screen circuit were sampled in order to measure and compare the performance of the circuits The ball mills are different in design Therefore simulation studies were carried out to eliminate the differences in factors affecting the performance of the circuits such as milling conditions

·In the case of ball mills all internal wearing parts will pass through the manhole whereas in the case of open end rod mills they will pass through the discharge trunnion opening When lining the shell start with the odd shaped pieces around the manhole opening if manholes are furnished Rubber shell liner backing should be used with all

Ball Mills work by employing various types of media either steel ceramic or lead balls to crush the material in the barrel To use the Mill the material to be ground is loaded into the barrel which contains grinding media As the barrel rotates the material is caught between the individual grinding media balls which mix and crush the

·In this paper we have highlighted some selected significant developments that have taken place during the last ten years or so in our understanding the size reduction of the particulate materials in ball mills using the traditional population balance model These developments relate to experimental technique and design of experiments nature of grinding

Find local businesses view maps and get driving directions in Google Maps

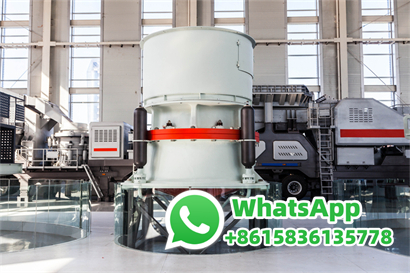

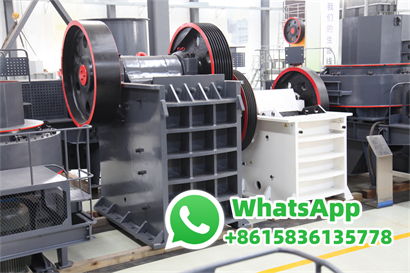

For this reason LAVAL LAB offers a wide selection of high performance mills in various product groups for every application and every specific need Planetary Ball Mills Ball Mills Cutting and Beater Mills Rotor Mills Jaw Crushers Roll Crushers Cone

·A Ball Mill Critical Speed actually ball rod AG or SAG is the speed at which the centrifugal forces equal gravitational forces at the mill shell s inside surface and no balls will fall from its position onto the shell The imagery below helps explain what goes on inside a mill as speed varies Use our online formula The mill speed is typically defined as the percent of the

The Planetary Ball Mill PM 300 is a powerful and ergonomic benchtop model with two grinding stations for grinding jar volumes up to 500 ml This setup allows for processing up to 2 x 220 ml sample material per batch Thanks to the high maximum speed of 800 rpm extremely high centrifugal forces result in very high pulverization energy and